At SIDEREAL, we're proud about how much we can detect through a thermal inspection. Not all these issues have to be solved today though. Some of them just have to monitored over time for example. Creating a punch list of work items can help you and your technicians focus on what has to be remedied today. Apart from that, you can also track issues that aren't related to anomalies we detected. You can use punch lists to track issues during the construction phase or to follow up and digitalize routine inspections.

This article covers the general functionality of punch lists. Check out the following articles for specific use cases:

ℹ️ What is a punch list?

A punch list is a list of work that still has to be done on site. Work is split into punch list items.

A punch list item should be a stand-alone piece of work that has to be done. Examples are a module that has to be replaced or checked, a structure that has to be moved or a tree that has to be trimmed. It should contain any information that's required to efficiently resolve it.

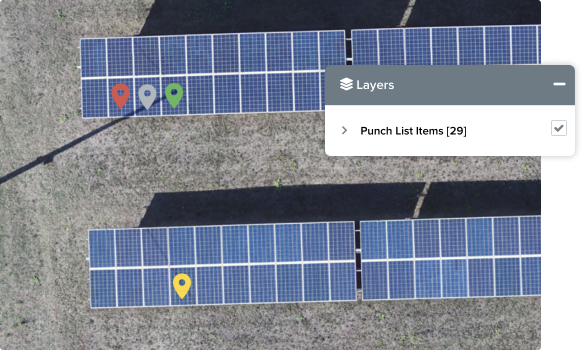

In the Fuse platform, each site has its own punch list. When you open any of the operations on that site, you'll see the Punch List Items in the layer manager. Because the punch list is stored on site level, they'll be visible in each operation. When data from a new operation comes in, you can thus evaluate if the existing punch list items are still valid and create new ones where needed.

🆕 Creating punch list items

There are three ways to create punch list items.

1️⃣ Single creation from an anomaly, element or annotation

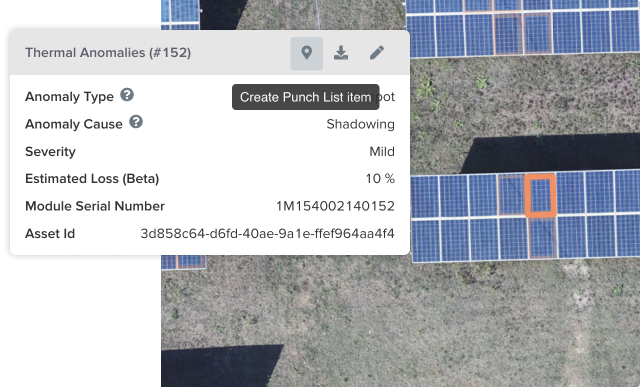

Both through the Fuse platform and the Field Link, you can create new punch list items from existing anomalies, elements or annotations. You can do this through the information popup of the feature, using the Create Punch List Item button.

The created punch list item will be linked to the anomaly, element or annotation for which you created it. For anomalies it automatically takes over any information required to resolve that anomaly. In the future, it will also enable historical analysis to see if the anomalies that were tackled don't resurface in future inspections.

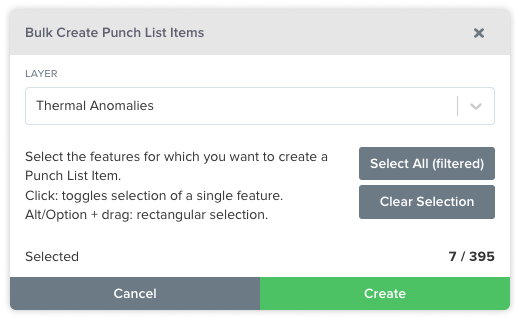

2️⃣ Bulk creation from anomalies, elements or annotations

To manage punch lists at scale, you need a way to create punch list items in bulk. When evaluating the results from the thermal inspection for example, you typically want to tackle all anomalies that adhere to some criteria, like a certain remedial action.

Learn more about managing remedial actions.

You can efficiently create anomalies in bulk by going to Bulk Actions and selecting Create Punch List Items.

You can select the layer for which you want to create punch list items: anomalies, elements or annotations. You can then select the features for which you want to create punch list items in 3 ways:

Click on the features on the map

Alt/Option + drag to select features on the map with a rectangle

Select all with filters

For most use cases, we recommend filtering out the anomalies on certain criteria, then selecting them all in the bulk creation.

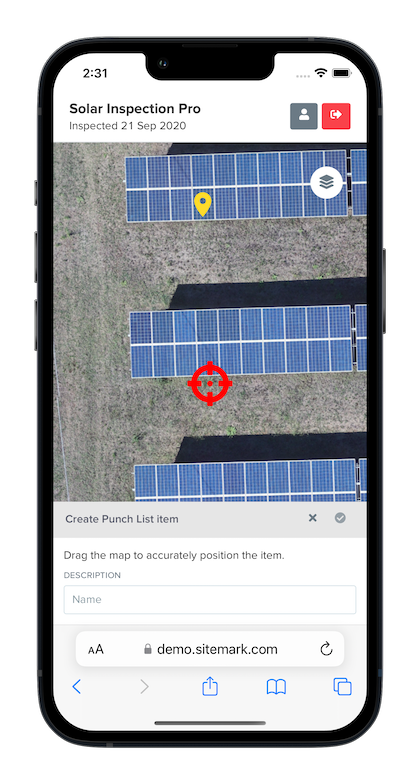

3️⃣ Single ad-hoc creation in the field

The first two methods are great to create tasks in the office and send them to your technicians, but it's also very valuable to let information flow in reverse. Technicians, workers or site managers who spot issues on site can create a punch list item to document it.

In the Field Link, you can use the Create Punch List Item button on the bottom left of the screen to create a new item. You give it a description and drag the map underneath the crosshairs to accurately position it.

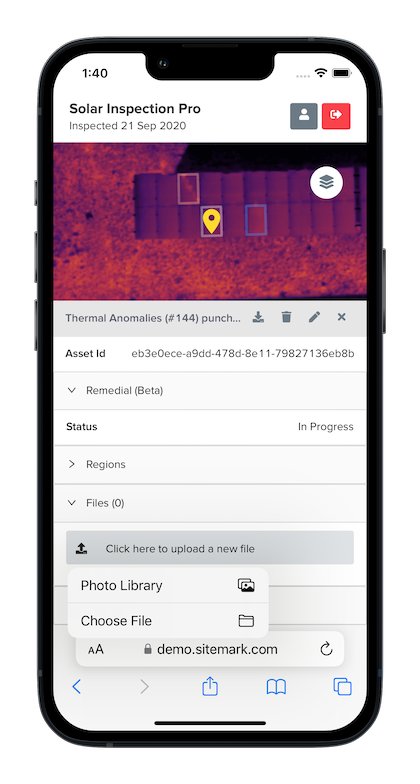

📸 Add information to a punch list item

When creating punch list items or when working on them in the field, you might want to add more information to it. This can be done in 2 ways:

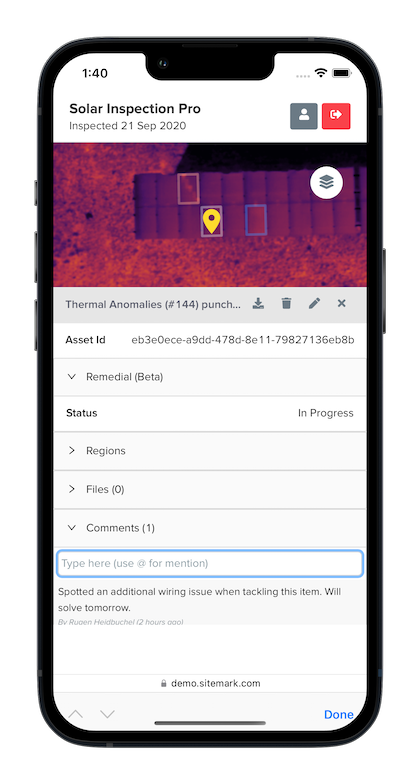

You can add attachments. This is useful to attach photos (visual and thermal), videos, IV curve measurements, CAD plans, etc.

You can add comments and tag users in the platform.