This article provides an in-depth explanation on the different thermal anomaly types that SIDEREAL identifies in your Solar Inspection Pro and in your Solar Inspection Essential data product. If you are looking for more details on the Solar Inspection Pro or Essential data product, check out the Solar Inspection Pro and Essential data product page.

In this article we will list the thermal anomalies and their symptoms. We mention the causes per type that lead to the thermal anomaly. For more in depth information about the causes, please go through this article. We also refer to the remedial action that might be applicable for the specific anomaly. For more in depth information about the remedial actions, please go through this article.

Thermal Anomaly Classifications

Hot Spot and Multi Hot Spots Issues

Symptoms

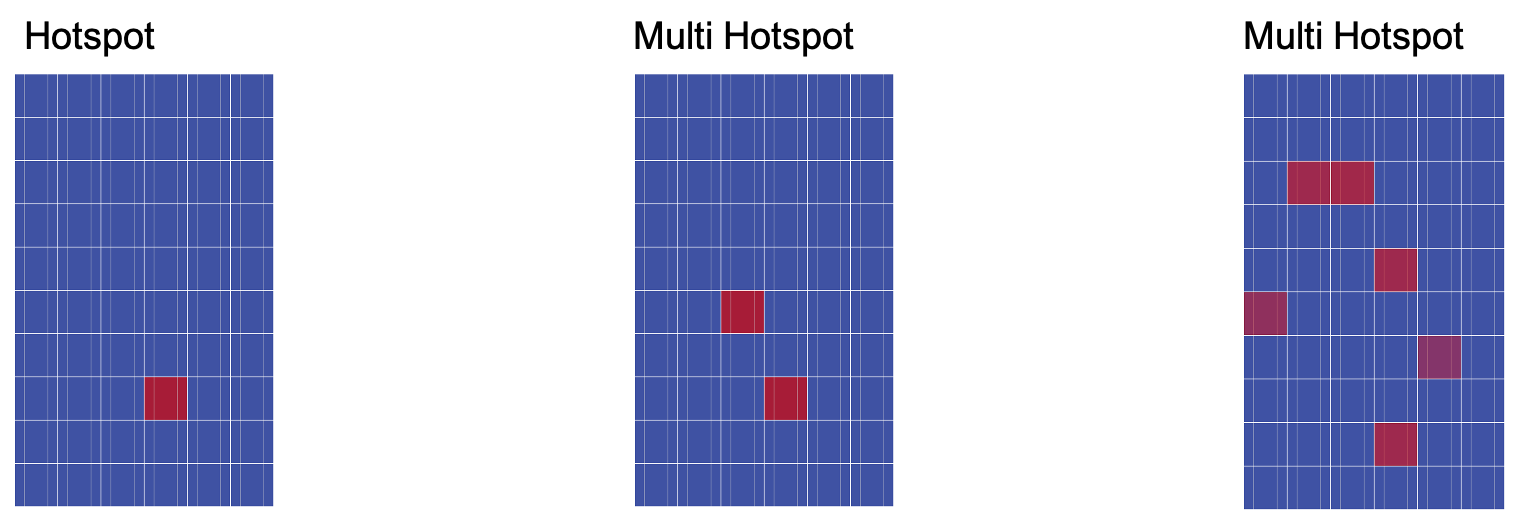

Hot Spots indicate a defect at the cell level, in which one or several cells have a higher temperature than the neighbouring ones.

Depending on the temperature difference between the cells, a Hot Spot may indicate a defect of varying levels of severity.

At SIDEREAL, we distinguish Hot Spots (only one cell appears to be impacted) and Multi Hot Spots (several cells of one PV module are unambiguously impacted).

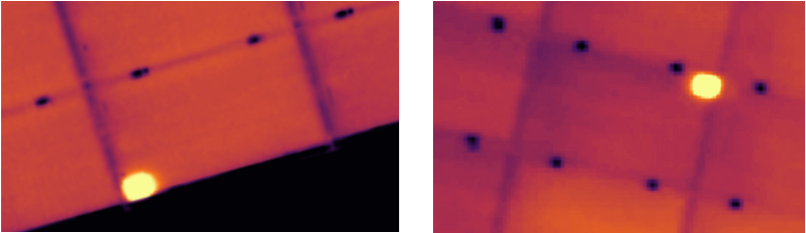

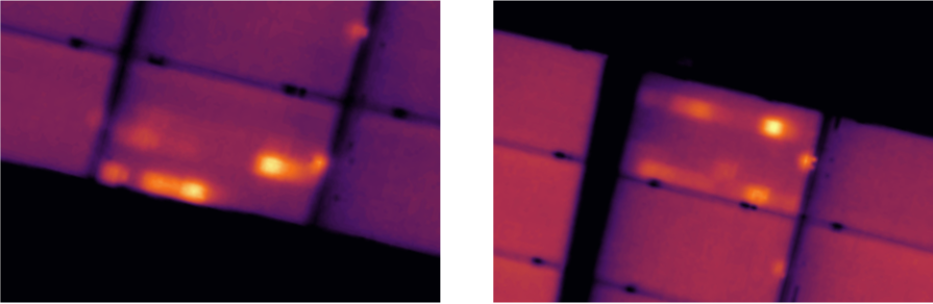

Some real examples showing a Hot Spot in the thermal image.

Causes

The causes of a Hot Spot can be numerous. Some causes are reversible, while others are not. Thermal images usually aren’t sufficient to identify the cause of a Hot Spot, but thanks to the use of the visual (RGB) photos, we are able to identify the main cause of the Hot Spot or Multi Hot Spots.

The most common causes come from external elements that would cast a shadow on the PV module. As a cell gets covered by shade, it turns into a resistor and will dissipate the energy produced by the other cells in the string. At SIDEREAL, we identify the cause according to the following categories:

Soiling of the PV modules: deposits of dust or dirt, leaves, etc.

Droppings: Bird droppings, which are frequent at the seaside or in industrial areas that involve food processing plants.

Vegetation: overgrown grass or plants that grow in front of the first row of PV modules or between the PV modules

Shadowing: external elements casting a shadow on the PV modules. Classic examples include physical elements bordering sites such as electrical poles, antennas, high tension cables, fences, trees, etc.

Physical defect: degraded PV modules or cells will show Hot Spots, but the underlying reason may not be visible to the naked eye, let alone from drone pictures. These would cover snail trails, micro-cracks, delamination, back-sheet issues, shattered glass, etc.

Remedial Actions

Depending on the cause, suggested remedial actions will vary:

Soiling: should the Hot Spot be caused by soiling or droppings, cleaning the PV modules can be sufficient to bring the PV module back to their nominal power output.

Vegetation: cutting the grass should be sufficient. However, some defects that are deemed reversible can bring long term damage to the PV modules if not promptly treated. We estimate that one season will be enough to turn a reversible Hot Spot into a non-reversible one, hence the importance of cleaning and cutting the grass at least once a year.

Shadowing: as causes of shadowing are usually external elements, no remedial action can be taken in most cases. The impacted PV modules should be monitored to assess whether the losses are affecting the production of non-impacted PV modules. The impacted PV modules may have to be replaced more often if the layout of the plant cannot be adapted to avoid the shadowed areas.

Physical defects: depending on the severity of the Hot Spot, the age of the plant and the underlying cause, physical defects may justify a warranty claim against the manufacturer. Acceptance criteria for warranty claims differ from one manufacturer to the next, but a commonly used threshold is a temperature delta of at least 20 degrees Celsius between the overheated cells and normally functioning ones.

Losses

Overheated cells acting as a resistor, will dissipate the energy generated by the other cells. Such cells will have an impact on the production of the full string of that PV module.

We generally assume that the losses will be proportional to the delta temperature of the Hot Spot, relative to the production level of the plant. Be aware that one Hot Spot on a string is capable of a causing a power production loss of up to 90% of the nominal production of one PV module.

Bypassed Substrings

Symptoms

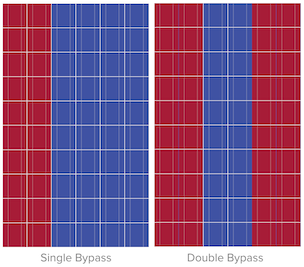

Cells in a solar module are organised in substrings, ie. chains of cells connected in series. A typical PV module includes three substrings of 20 or 24 cells each (depending on the PV module type). To prevent shaded or broken cells from impacting the production of the whole string, these substrings can be bypassed thanks to bypass diodes.

These substrings will then be isolated and won’t produce any energy at all. As a result, they will have a higher temperature than the cells working normally in the same PV module. The defect can then be seen on the thermal images with one third, two thirds or even the whole of the PV module being warmer than the neighbouring ones.

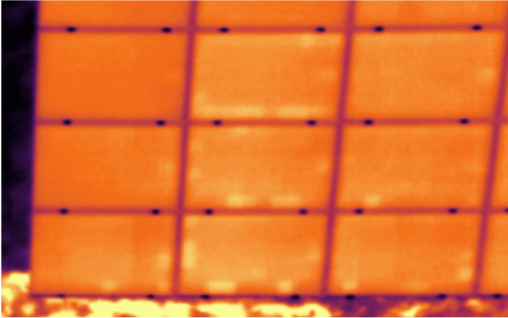

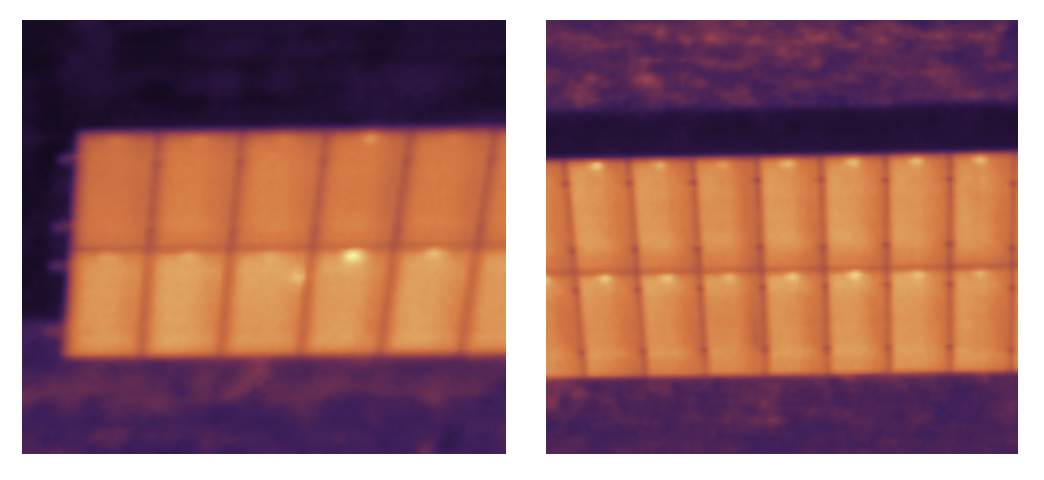

Some real examples showing a single bypassed substring in the thermal image.

Some real examples showing a double bypassed substring in the thermal image.

Causes

Bypassed substrings are a fail-safe mechanism of the PV modules. Generally speaking, this is expected behaviour when the cause of the shading is visible and the defect disappears when the cause of the shading is fixed.

However, bypassed substrings can be persistent in two main cases:

The bypass diode is damaged and will always isolate a substring despite the cause having been fixed

The substring is physically disconnected and can’t let any current through

Remedial Actions

In most cases, bypassed substrings are reversible defects and will disappear as soon as the cause is fixed. In the event a bypassed substring is present despite no cause being visible, the most relevant fix would be to consider replacing the PV module. Depending on the age of the plant and the cause of the issue, manufacturers may cover the replacement of impacted PV modules under warranty.

Power Losses

For a single bypassed substring one-third of the PV module is disconnected, the power loss will be as high as one-third (33,33%) of the entire power production of one module.

For a double bypassed substring two-thirds of the PV module is disconnected, the power loss will be as high as two-thirds (66,66%) of the entire power production of one module.

Single Diode and Multi Diode Issues

Symptoms

PV modules with several cells at a high temperature can be classified as Multi Hot Spots. However, if these cells appear to be located in the same substring, the cause of the problem lies in the diode of that substring. One will typically see very high-temperature variations between the cells in one-third of the PV module, while the rest of the PV module has a homogeneous temperature. This is what we call a single diode issue.

Some real examples showing a single diode issue in the thermal image.

Similar to a single diode issue, the multi diode issue has more than one substring affected. The difference compared to a multi hotspots issue is that the anomalies follows the line of the substrings and appear linear in nature.

Some real examples showing a multi diode issue in the thermal image.

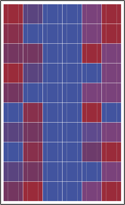

This defect is different from a single or a double bypassed substring. In a bypassed substring issue, the affected cells have the same temperature. In the case of a single or a multi diode issue, all cells are hotter, but the thermographic images will show an irregular checkerboard pattern on that substring.

Causes

The diode designed to bypass the substring is damaged and will always let current through. Such damage can typically be caused by a very high current going through the PV module, due to lightening for example, leading to a permanent malfunction of the diode.

Remedial Actions

If replacing the diode is not an option, the full PV module will have to be changed.

Power Losses

Although complex to accurately calculate, the power losses can be estimated to be up to a third of the module’s nominal production, per substring impacted.

Potential Induced Degradation (PID) Issues

Symptoms

PV modules show a checkerboard pattern on the thermal images. Significant temperature differences are visible between the cells. This type of defect usually impacts several contiguous PV modules, and usually at the end of a string, i.e. close to the negative pole of the string.

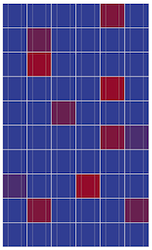

An example showing a PID issue in some of the PV modules.

Causes

Potential Induced Defects (PID) are caused by a voltage difference between the cells and the frame of the PV modules. This difference may cause residual leakage current to flow through the cells and impact the yield significantly.

This effect is thought to be largely impacted by the following parameters:

Grounding of the PV modules frames, the piles, etc.

The choice of the inverter and its working mode, specifically the potential differences between the piles and the ground that the inverter is set at.

PV module design, including the type of insulation used, the silicon wafer type, mechanical design of the frame, etc.

Remedial Actions

Not all causes of PID issues can be acted upon, which leaves the operator with a limited choice.

The main remedial actions include:

Check the grounding of the frames, PV module rows and inverters to assess whether the grounding could be improved. A thorough inspection of the impacted strings and rows may lead to some insight into the underlying causes of PID.

As a short term fix, swap PV modules from the positive end to the negative end of the string to avoid physical problems developing in the PV modules over time.

Consider changing the working mode of the inverters (if possible) to change the voltage difference between ground and inverter poles.

Consider commercial solutions that inject a very small reverse current at night to counteract the effects of PID.

Power Losses

Leak currents and overheating of cells will dissipate energy that would otherwise be converted by the inverter. A commonly accepted estimate in the scientific community is that power losses per PV module impacted may be as high as 30%. PID issues tend to get worse over time.

Potential PID Issues

Symptoms

The definition and threshold for the classification of PID vary throughout the industry. At SIDEREAL, we not only mark PID but we also mark the PV modules that show an early-stage behaviour similar to PID. For example, these show warmer cells close to the edges of the PV modules, indicating that the cause of the temperature increase can be found in a voltage difference. And we mark only the PV modules that have more than one edge impacted by such an effect, as the example below shows.

An example showing a Potential PID issue in some of the PV modules.

Remedial Actions

Similar to PID, but with no short term actions recommended. These defects can also indicate the normal wear and tear of the PV modules due to the age of the installation. Proper monitoring of the status of these PV modules is recommended to observe how the situation evolves.

Power Losses

Temperature differences undoubtedly indicate power losses, but it is assumed that such PV modules will cause lower power losses than actual mature PID.

String Issues

Symptoms

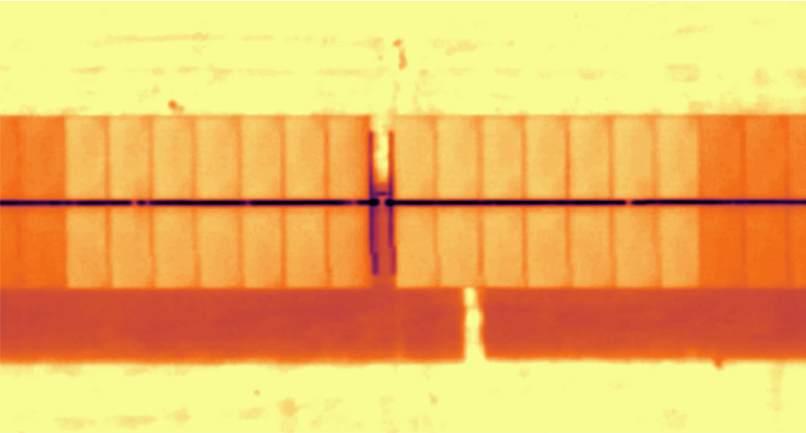

One group of PV modules is warmer than another comparable group of PV modules by a few degrees, but the temperature is uniform across the impacted group.

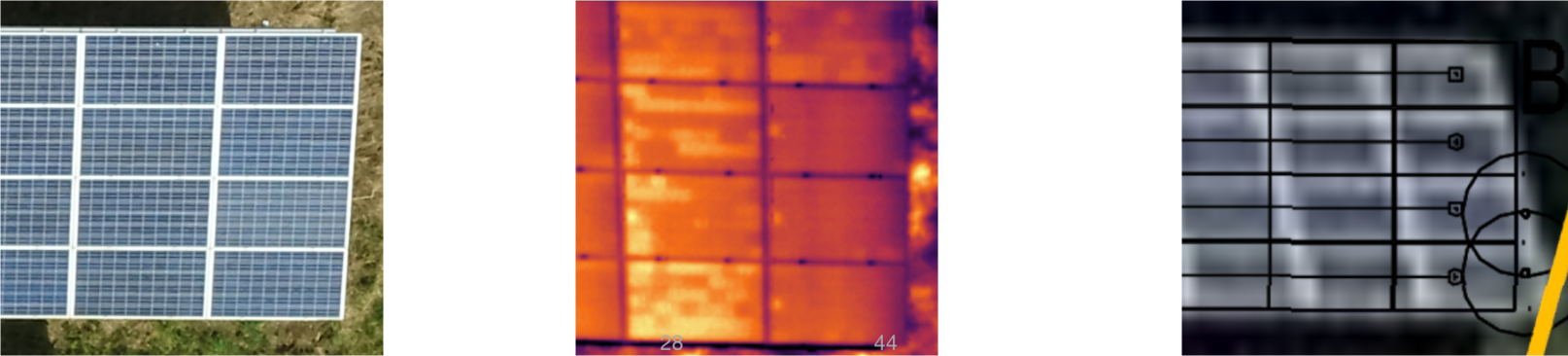

An example showing a string issue in the thermal image.

Causes

The full string is disconnected and gets warmer because the solar irradiance isn’t converted into power. The PV modules in the affected string absorb the solar irradiance and that is why the surface of the PV modules in this string are hotter than the neighbouring string. This may occur due to several issues such as:

a blown fuse,

a disconnected cable,

a damaged or burnt welding point,

a physical issue in a connection box or at the inverter,

any issue that could cause a physical disconnection or prevent current from flowing through the string.

Remedial Actions

Start with a thorough check of the string connections, these remedial actions should be simple. Since these issues cause extreme power losses and are often easy to fix, they should be treated with the highest level of priority.

Power Losses

When an entire string of PV modules is disconnected, these PV modules are not producing any power. This means that the power loss is 100%. for as long as the string issue has existed.

Open PV Module

Symptoms

One PV module is warmer than the other PV modules by a few degrees, but the temperature is uniform across the impacted module.

An example showing an open module issue in the thermal image.

Causes

The complete PV module is disconnected and gets warmer because the solar irradiance isn’t converted into power. The PV module absorbs the solar irradiance and that is why the surface of the PV module is hotter than the neighbouring module. This may occur due to several issues such as:

a blown fuse,

a disconnected cable,

a damaged or burnt welding point,

a physical issue in a connection box or at the inverter

Power Losses

When an entire PV module is disconnected, it means that this module is not producing any power. This means that the power loss is 100%.

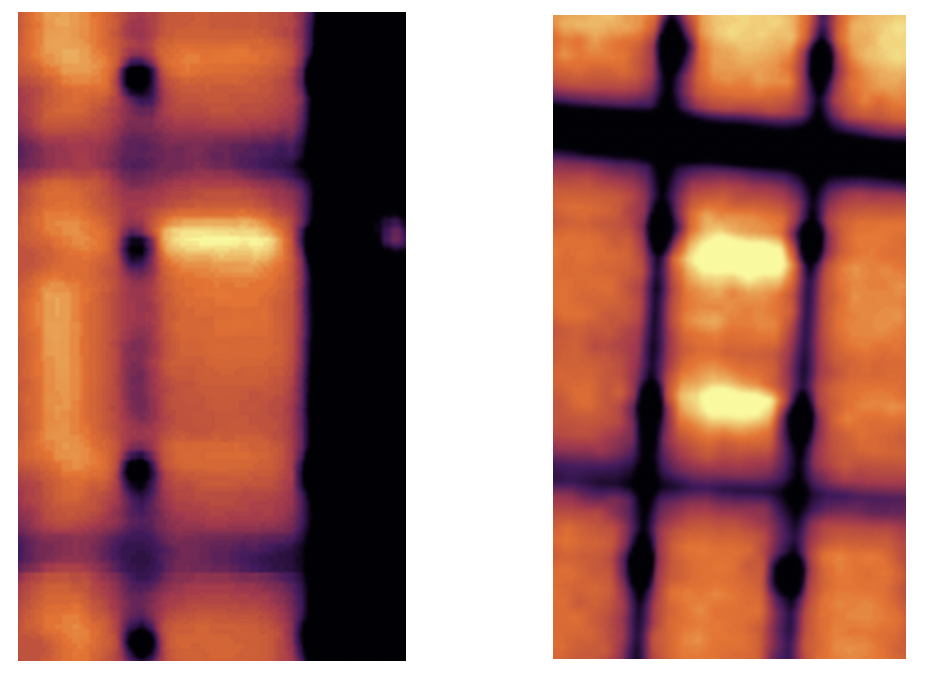

Heated Junction Box Issues

Symptoms

It is expected that junction boxes would slightly warm up, because of the high current density it undergoes, but however a high temperature may indicate issues in the connections that will cause power losses or even a fire hazard.

Any heat generated in the junction box is thus dissipated through the back-sheet, wafer and glass layers before it can get measured. This information is what we use to try and assess whether a junction box has a problem, or not.

Our assessment of the health of junction box is thus mainly relative, comparing the brightness of junction boxes compared to its neighbouring ones. This is based on the assumption that if a majority of the PV modules show a warm junction box, they are not likely to be faulty. The increase in temperature can indeed be due to a high irradiance or specific PV module design.

The example below on the left shows one junction box being warmer than the surrounding ones indicating a potential problem. The example below on the right shows PV modules in which the temperature of the junction boxes looks similar across all PV modules.

Be aware that the location of the junction box may differ depending on type of PV module.

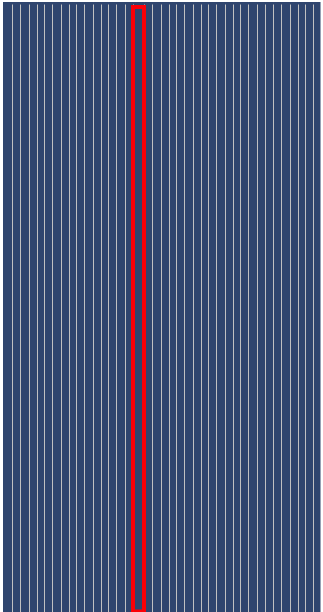

Thin File Single Cross Cell and Multi Cross Cell

Symptoms

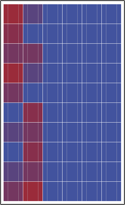

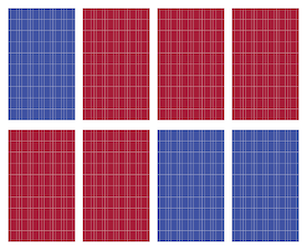

The thin film cross cell and multi cross cell anomalies are similar to the hotspot and multi hotspot anomalies seen on mono/polycrystalline panels. The difference however between mono/polycrystalline and thin film panels is that the cells in a thin film panel are long and thin as shown in the schematic below (one cell is identified by the red rectangle).

Single Cross Cell Multi Cross Cell

Causes

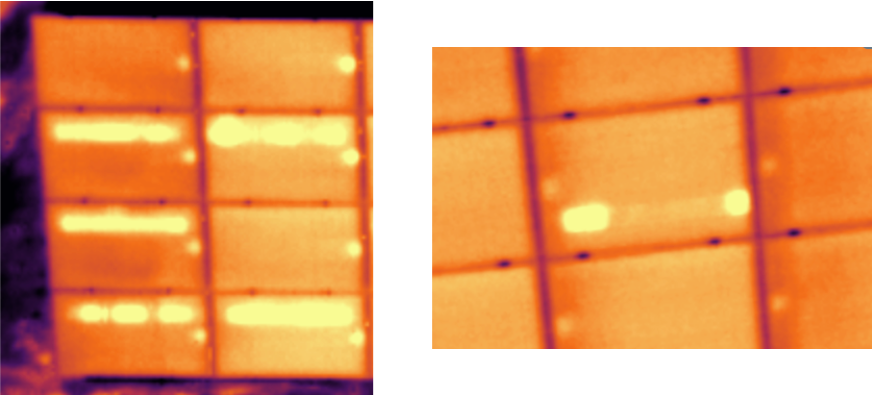

As a consequence of the narrow cells, some anomalies that would be classified as hot spots and multi hotspots on mono/polycrystalline panels do not appear as a single point hotspot in the thermal imagery for thin film panels. The anomaly appears elongated and can appear to cross a number of adjacent cells and sometimes the complete width of the panel, as shown in the thermal examples above.

The cause of the thin film cross cell anomalies could be related to a potential physically internal problem with the panel itself or could be due to the presence of broken glass, which is not visible in the RGB imagery.

Based on the severity of the anomaly it is recommended to either monitor the anomaly, for low temperature delta anomalies, or for anomalies with a severity of Critical then it is recommended to repair the panel.

Power Losses

Although complex to accurately calculate, due to the extent of the panel covered by the anomaly, power losses can at times be up to a third of the module’s nominal production.